Powder Coating

© Ginko Metal Works LLC

Made with Xara

Powder Coating

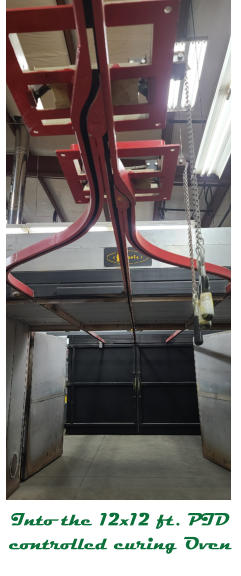

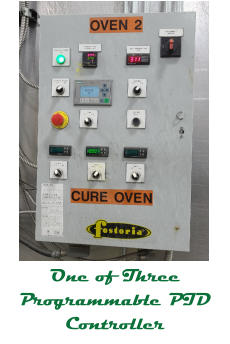

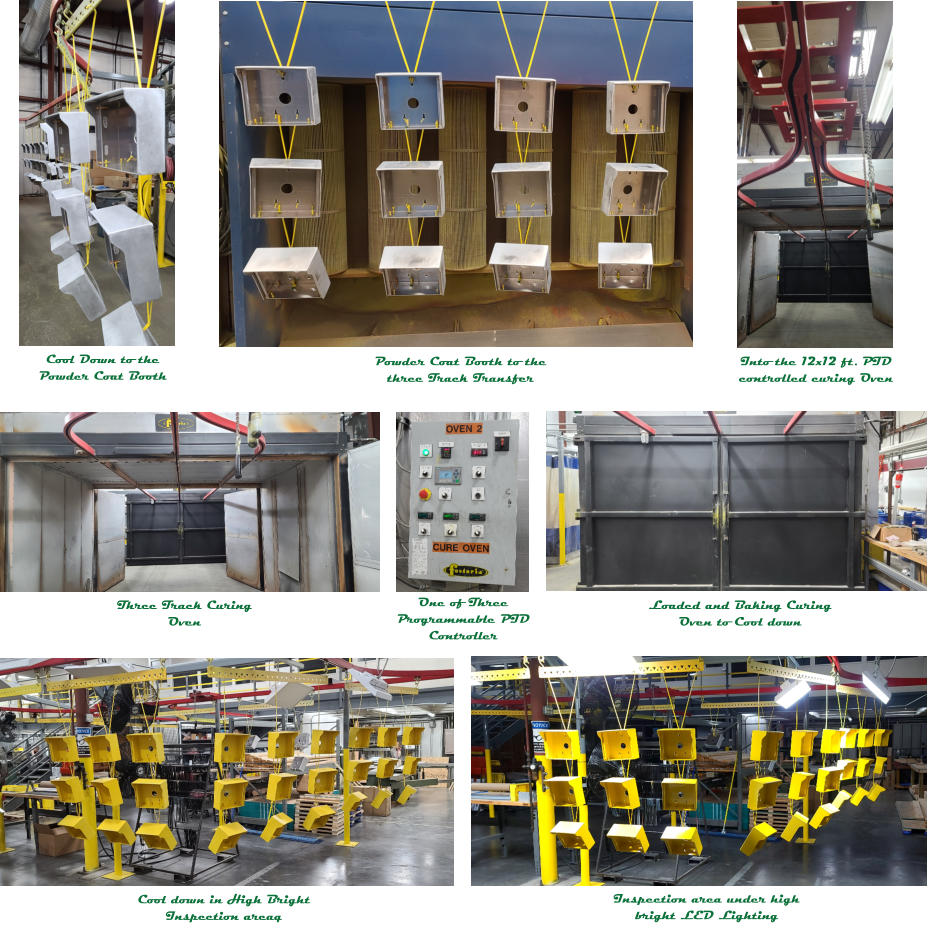

A product is only as good as the its protection. We offer a wide variety of protection options, including our newly added fully operational Powder Coat line. Our Powder coat system includes a power wash station booth feeding to a PID Temperature control 6x9 foot drying oven. After the drying oven, it goes to a cool down area before entering the powder coat booth. The powder coat booth has a massive filter system which aids in the coating, and reduces contamination when colors are changed. From the Booth, the parts go to the massive three rail 12x12 foot curing PID controlled ovens. The part is then moved to our cool down area, and inspected under intensive inspection lighting. We can provide the type and color of coating to meet your specifications, whether it’s a Pantone® Colors, custom registered colors, or a one off color, we will meet your spec. Equipment and supplies are only as good as those who use them, and Powder Coat is no different. To that end we have assembled a team with members with over 30 years personal experience in the coating and treating business. We are proud of the team we have assembled. So, regardless if it’s Painting, Plating, Anodizing, or Heat Treating we will treat your job as if it was our own. You can be assured that we only use the best methods and most reliable resources. We have also added a Chemical Coating and Passivation line for applications where Paint or Powder are not the answer, including Military and Aviation requirements. To see more about these abilities please Click HERE .

Powder Coating

Laser Cutting

Machining

Punching

Welding

© Ginko Metal Works LLC

Made with Xara

Powder Coating

A product is only as good as the its protection. We offer a wide variety of protection options, including our newly added fully operational Powder Coat line. Our Powder coat system includes a power wash station booth feeding to a PID Temperature control 6x9 foot drying oven. After the drying oven, it goes to a cool down area before entering the powder coat booth. The powder coat booth has a massive filter system which aids in the coating, and reduces contamination when colors are changed. From the Booth, the parts go to the massive three rail 12x12 foot curing PID controlled ovens. The part is then moved to our cool down area, and inspected under intensive inspection lighting. We can provide the type and color of coating to meet your specifications, whether it’s a Pantone® Colors, custom registered colors, or a one off color, we will meet your spec. Equipment and supplies are only as good as those who use them, and Powder Coat is no different. To that end we have assembled a team with members with over 30 years personal experience in the coating and treating business. We are proud of the team we have assembled. So, regardless if it’s Painting, Plating, Anodizing, or Heat Treating we will treat your job as if it was our own. You can be assured that we only use the best methods and most reliable resources. We have also added a Chemical Coating and Passivation line for applications where Paint or Powder are not the answer, including Military and Aviation requirements. To see more about these abilities please Click HERE .

© Ginko Metal Works LLC

Powder Coating

A product is only as good as the its protection. We offer a wide variety of protection options, including our newly added fully operational Powder Coat line. Our Powder coat system includes a power wash station booth feeding to a PID Temperature control 6x9 foot drying oven. After the drying oven, it goes to a cool down area before entering the powder coat booth. The powder coat booth has a massive filter system which aids in the coating, and reduces contamination when colors are changed. From the Booth, the parts go to the massive three rail 12x12 foot curing PID controlled ovens. The part is then moved to our cool down area, and inspected under intensive inspection lighting. We can provide the type and color of coating to meet your specifications, whether it’s a Pantone® Colors, custom registered colors, or a one off color, we will meet your spec. Equipment and supplies are only as good as those who use them, and Powder Coat is no different. To that end we have assembled a team with members with over 30 years personal experience in the coating and treating business. We are proud of the team we have assembled. So, regardless if it’s Painting, Plating, Anodizing, or Heat Treating we will treat your job as if it was our own. You can be assured that we only use the best methods and most reliable resources. We have also added a Chemical Coating and Passivation line for applications where Paint or Powder are not the answer, including Military and Aviation requirements. To see more about these abilities please Click HERE .

Three Track Curing Oven